The Significance of Creo 11 for Automotive and Manufacturing Industries

Introduction to Creo 11

Creo 11 stands as a pivotal design software in the manufacturing sector, offering innovative solutions tailored to meet the increasing demands of modern industry. Developed by PTC, Creo has undergone a significant evolution since its inception. Since the launch of its first version, Creo has progressively enhanced its capabilities to provide comprehensive 3D CAD tools that facilitate product design and engineering.

The transition from earlier iterations of Creo to version 11 marks a notable milestone, incorporating feedback from industry professionals and addressing specific challenges faced by manufacturers. One of the critical areas of focus in the latest release is the integration of advanced technologies such as generative design and augmented reality. These features empower engineers and designers to create optimized designs that improve performance while reducing production costs.

Manufacturers, particularly in the automotive industry, contend with unique challenges including shorter product development cycles, the need for customization, and adherence to rigorous safety and regulatory standards. Creo 11 addresses these issues through streamlined workflows and enhanced collaboration tools that promote efficiency and innovation. Furthermore, its capabilities for direct modeling and parametric design make it particularly suited for the fast-paced automotive environment, where adaptability and precision are crucial.

Another notable enhancement in Creo 11 is its cloud-based collaboration options, which allow teams to work together seamlessly, regardless of their physical locations. This flexibility is crucial in today’s globalized market, where engineering teams are often dispersed across different countries and time zones. By leveraging these advanced features, Creo 11 provides manufacturers with the ability to remain competitive in an ever-evolving landscape.

In essence, Creo 11 represents a significant advancement in design software, offering the tools necessary for manufacturers to overcome contemporary challenges while fostering innovation and efficiency.

Key Features of Creo 11

Creo 11 stands out with its advanced features tailored for the automotive and manufacturing industries. One of the most significant enhancements is its generative design capability, which empowers engineers to create optimal design alternatives based on specified constraints such as weight, materials, and performance criteria. This innovative approach not only accelerates the design process but also leads to more efficient and sustainable solutions. By leveraging generative design, manufacturers can produce components that are lighter and stronger, thereby improving the overall performance of their vehicles or machines.

In addition to generative design, Creo 11 incorporates augmented reality (AR) functionalities. AR allows users to visualize their designs in a real-world environment, enabling better understanding and evaluation of the final product before moving into production. This capability facilitates collaboration among design teams, clients, and stakeholders, ensuring that feedback can be easily integrated into the design process. As a result, automotive manufacturers can minimize costly revisions and enhance customer satisfaction through more accurate representations of the end product.

Another key feature of Creo 11 is its integration of artificial intelligence (AI). The tool uses AI-driven recommendations to assist engineers in making data-informed decisions throughout the design and manufacturing processes. By analyzing production data and design parameters, Creo 11 can suggest improvements, identify potential design flaws, and optimize workflows. This AI integration drastically increases efficiency and reduces time-to-market for new vehicles and components, making it an indispensable asset for automotive manufacturers seeking to maintain a competitive edge.

Overall, the features within Creo 11 are designed to elevate productivity and encourage innovation. The combination of generative design, augmented reality, and artificial intelligence not only streamlines the design process but also enhances the overall quality of products in the automotive and manufacturing sectors.

The Importance of Design Efficiency

Design efficiency plays a pivotal role in the automotive manufacturing sector, influencing not only the speed of production but also the quality and innovation of the final product. With the ever-increasing demand for advanced vehicles and competitive market pressures, design teams must optimize their workflows to meet these challenges effectively. Creo 11 has emerged as a significant solution to enhance design efficiency, enabling teams to reduce time-to-market while elevating product quality.

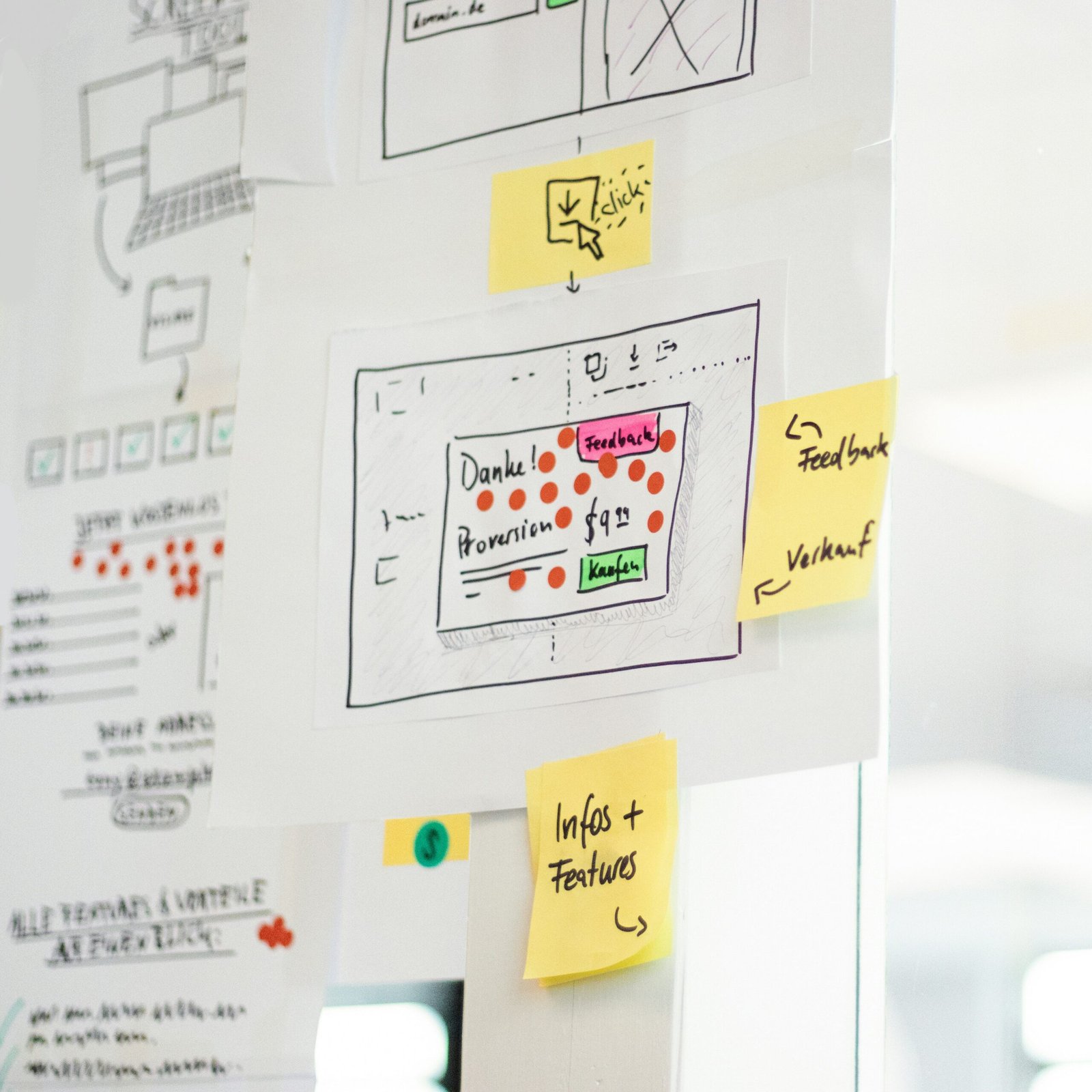

One of the standout features of Creo 11 is its focus on collaboration. In a complex automotive design environment, multiple stakeholders—designers, engineers, and project managers—need to work together seamlessly. Enhanced collaboration tools facilitate real-time sharing of design files and feedback, ensuring that everyone involved is aligned with the project’s goals. This ability to work concurrently reduces the time required for design iterations, allowing teams to address issues swiftly and implement suggestions from different departments efficiently.

Moreover, Creo 11 integrates advanced simulation capabilities that allow designers to assess the performance of their designs virtually. By simulating real-world conditions during the design phase, engineers can identify potential failures and optimize performance without the resource drain of physical prototypes. This approach not only accelerates the design process but also contributes to a higher standard of safety and reliability, critical factors in automotive manufacturing.

In conclusion, the importance of design efficiency within the automotive industry cannot be overstated. Tools such as Creo 11 empower design teams to collaborate effectively, iterate quickly, and leverage powerful simulation capabilities. By incorporating these advanced features, automotive manufacturers can enhance their design processes and bring innovative products to market faster, ultimately meeting consumer demands more effectively and sustaining competitive advantage in the industry.

Enhanced Collaboration Across Teams

In today’s fast-paced automotive and manufacturing industries, collaboration among cross-functional teams is paramount to ensuring efficiency and innovation. Creo 11 offers a suite of tools that significantly enhances collaborative efforts across various departments, facilitating seamless communication and teamwork. One of the standout features of this software is its shared views functionality, enabling team members to view and interact with design models in real time. This capability is particularly valuable in a landscape where multiple stakeholders, including engineers, designers, and project managers, must work interactively on complex projects.

The ability to share views allows all team members to contribute their insights and opinions directly on the design, promoting immediate feedback that can be incorporated into iterations. This collaborative approach not only accelerates the design process but also helps align different perspectives, ensuring that everyone is on the same page. Moreover, real-time editing capabilities mean that changes can be made dynamically, allowing teams to adapt quickly to new requirements or constraints that may arise during development cycles.

Furthermore, Creo 11’s integration with cloud services facilitates remote collaboration, an increasingly essential feature in today’s global economy. With teams often operating from different geographical locations, the ability to collaborate effortlessly online enhances productivity and ensures that geographic barriers do not impede project timelines. Automotive companies, in particular, stand to benefit from this feature, as they often engage diverse teams to address various elements of design, regulatory requirements, and market demands. By fostering enhanced collaboration through tools such as shared views and real-time editing, Creo 11 helps automotive and manufacturing companies achieve successful product launches, thus maintaining their competitive edge in the marketplace.

Integration with Other Software and Systems

Creo 11 is designed to enhance productivity in the automotive and manufacturing sectors by ensuring excellent interoperability with a variety of essential software and manufacturing systems. Its capabilities extend beyond mere design tools, allowing for seamless integration with Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems. This level of integration is crucial for creating a cohesive workflow that optimizes efficiency in production processes.

One of the key advantages of integrating Creo 11 with PLM systems is the ability to streamline the management of product data throughout its lifecycle. This allows teams to access real-time information about design changes, revisions, and compliance requirements, which minimizes errors and improves collaboration across departments. By incorporating Creo 11 into a PLM framework, organizations can facilitate better decision-making and ensure that all stakeholders are aligned on project objectives and updates.

Moreover, the compatibility of Creo 11 with ERP software enhances the connection between design and manufacturing. With this integration, essential data such as bill-of-materials, cost information, and production timelines can be shared effortlessly. Consequently, the integration enables manufacturers to adjust production plans quickly in response to changes in design or market demand, ultimately leading to shorter lead times and reduced production costs.

Another significant point is the role of Creo 11 in integrating with other collaborative tools, fostering a digital ecosystem that supports remote teams and enhances communication. This connectivity helps ensure that all members involved in the design and production process can cooperate effectively, regardless of their physical location.

In conclusion, the integration capabilities of Creo 11 with PLM, ERP, and other software systems are vital in formulating an efficient and cohesive manufacturing framework. Such integrations help improve workflows, reduce time to market, and support superior product quality within the automotive and manufacturing landscapes.

Sustainability and Cost Management

In today’s automotive and manufacturing industries, sustainability and cost management are critical factors driving innovation and competitive advantage. Creo 11 plays a pivotal role in fostering sustainable manufacturing practices, providing tools that help organizations optimize their processes while aligning with environmental goals. Among its features, Creo 11 introduces advanced design capabilities that allow engineers to create products with a focus on material efficiency. This optimization not only reduces the amount of material being used but also minimizes waste generated during the production phase.

One notable aspect of Creo 11 is its enhanced simulation capabilities. By accurately predicting how materials will behave under various conditions, manufacturers can select the most suitable materials for their specific applications. This results in a reduction in over-engineering and encourages the use of lightweight materials, significantly lowering the energy consumption associated with manufacturing and logistics. Furthermore, by using digital tools to simulate and optimize designs, companies can identify issues early in the development process, thereby decreasing costly revisions and production delays.

Moreover, Creo 11 features integrated tools for lifecycle assessment, empowering manufacturers to evaluate the environmental impact of their products throughout their entire life cycle. This holistic view allows organizations to make informed decisions concerning material selection and resource allocation, further enhancing sustainability while keeping costs in check. By aligning product design with sustainable practices, businesses can not only meet regulatory requirements but also cater to a growing consumer demand for environmentally friendly products.

In conclusion, the innovative functionalities offered by Creo 11 are instrumental in promoting sustainable manufacturing. By optimizing material usage and minimizing waste, manufacturers can significantly improve their cost management strategies while adhering to modern sustainability demands, facilitating a more eco-conscious approach in the automotive and manufacturing sectors.

Successful Implementation of Creo 11

The adoption of Creo 11 by various manufacturers and automotive companies showcases the software’s transformative impact on design and production processes. One notable case is that of a leading automotive manufacturer that implemented Creo 11 to streamline its design workflow. Prior to this implementation, the company faced challenges in integrating various design elements efficiently, which often resulted in delays in production timelines. By adopting Creo 11, the manufacturer was able to utilize advanced parametric modeling features and collaborative tools, leading to a significant reduction in time-to-market for new vehicle models.

In addition to time savings, this company reported increased productivity due to Creo 11’s ability to enable simultaneous editing by multiple designers. This capability allowed teams to work in unison, fostering a more collaborative environment. Furthermore, enhanced visualization tools offered by Creo 11 empowered designers to refine their concepts early in the development cycle. As a result, the quality of final designs improved, leading to fewer iterations and revisions, which ultimately further streamlined production processes.

Another example can be found in the aerospace sector, where a prominent manufacturer adopted Creo 11 for its intricate design requirements. This company benefited from the flexibility and parametric capabilities of Creo 11, enabling engineers to tackle complex designs with ease. The software’s simulation features allowed for thorough testing of components before physical prototypes were created, reducing material waste and costs associated with traditional prototyping methods. The result was not only enhanced design capabilities but also a significant increase in market responsiveness, as the company was able to adjust designs rapidly based on customer feedback.

These case studies illustrate that the successful implementation of Creo 11 leads to tangible benefits, including increased productivity, superior design capabilities, and improved adaptability to market demands, ultimately positioning companies for sustained growth in the competitive automotive and manufacturing industries.

Future Trends in Manufacturing and Design Software

The rapid evolution of manufacturing and design software is shaping the landscape of various industries, with Creo 11 serving as a prime example of this transformation. As developments in technology continue to influence the manufacturing sector, several emerging trends can be observed that industries should monitor closely to maintain a competitive edge.

One of the most significant trends is the integration of artificial intelligence (AI) and machine learning into design processes. These technologies can enhance decision-making by enabling designers to predict outcomes based on historical data and trends. AI-driven tools in Creo 11 allow for improved design iterations and optimization, ultimately resulting in more efficient product development. Such advancements reflect a shift toward data-centric methodologies, which will increasingly govern how products are conceptualized, developed, and manufactured in the future.

Another critical trend is the emphasis on sustainability and eco-friendly design practices. As environmental concerns gain traction, manufacturers are compelled to adopt sustainable methods that minimize waste and reduce carbon footprints. Creo 11 supports these initiatives by incorporating tools that assess the environmental impact of design choices, allowing companies to analyze and optimize products for sustainability. This approach not only meets regulatory requirements but also addresses the growing consumer demand for environmentally conscious products.

The rise of additive manufacturing, or 3D printing, is also transforming traditional manufacturing practices. With the capabilities of Creo 11 to create complex geometries and integrate with various 3D printing technologies, manufacturers can explore new possibilities for customization and rapid prototyping. This shift is indicative of a broader move towards flexible manufacturing systems that prioritize efficiency and responsiveness to market demands.

Lastly, the increasing importance of collaboration and communication tools in design and manufacturing cannot be overlooked. Virtual collaboration using cloud-based systems and advanced visualization tools offered by Creo 11 will facilitate more efficient project management and team interactions, allowing companies to respond swiftly to changing market conditions. This focus on collaborative design is essential in an era where innovation is key to sustaining competitive advantage.

Conclusion

Creo 11 has emerged as a pivotal tool in the realm of automotive and manufacturing industries, redefining how companies approach design, engineering, and production processes. By integrating advanced design technologies into their workflows, organizations can significantly enhance their operational efficiency, product innovation, and competitiveness in the market. The transition to Creo 11 symbolizes a broader shift towards digitization and automation that is essential for modern manufacturers.

The software’s robust capabilities in 3D modeling, simulation, and product lifecycle management allow teams to collaborate more effectively and reduce time-to-market while simultaneously improving the quality of their products. With its user-friendly interface and comprehensive feature set, Creo 11 enables designers and engineers to easily adapt to the complexities of contemporary manufacturing demands, making it indispensable for organizations aiming to maintain relevance in an evolving landscape.

Moreover, the emphasis on sustainability in manufacturing aligns with Creo 11’s functionalities, which support eco-friendly practices through efficient design processes and materials management. As industries face increasing pressure to minimize their environmental impact, leveraging advanced tools such as Creo 11 becomes a critical step for companies aspiring to meet regulatory demands and consumer expectations.

In conclusion, adopting Creo 11 is not merely a technological upgrade; it represents a strategic shift that positions businesses for future success. As automotive and manufacturing sectors continue to evolve, integrating sophisticated design software like Creo 11 is essential for organizations targeting growth and resilience. Embracing this advanced technology paves the way for innovation and ensures that companies remain competitive and sustainable in an ever-challenging market environment.